Photo Credit: Tim Southers/NASCAR

LAS VEGAS — The K&N Pro Series is set to show off the hottest new body on the Las Vegas Strip and NASCAR is convinced that it’s hit the jackpot thanks to the model’s curvaceous collaboration of substance and speed.

In fact, the sport is betting that drivers and crew chiefs alike will be unable to keep their hands off the sleek and sexy lines of their show-stopper that will be unveiled Tuesday by NASCAR President Mike Helton during the SEMA automotive specialty products trade show at the Las Vegas Convention Center.

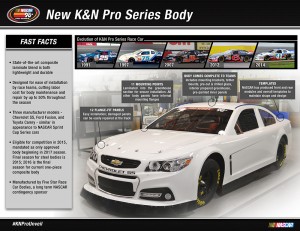

“This car is not only a pretty good-looking piece, it’s a game changer,” said NASCAR Touring Series Managing Director Brad Moran of the new body, sporting panels made from a state-of-the-art composite laminate blend that are bolted together with a revolutionary 12-flange design.

Built with aerodynamics, safety and cost-effectiveness in mind, the body will replace existing steel-shelled K&N cars with a design that’s 35 pounds lighter and miles ahead of the competition when it comes to ease of repair.

Previously seen only by a handful of racing officials outside the Turner Motorsports shop in Mooresville, North Carolina, the Las Vegas car is painted to replicate 2014 K&N Pro Series East champion Ben Rhodes’ current Chevrolet Impala SS. Equipped with a Robert Yates spec engine, the Vegas model is white with blue, green and red stripes along the side. It carries the number 41 as well as the name of Rhodes’ sponsor, Alpha Energy Solutions, on the quarter panels and hood.

“I don’t get too excited to debut too many new cars, but this one, with a red chassis and the white body looks like a show car,” says Mike Greci, K&N East Series Director for Turner Motorsports, whose team was responsible for assembling and prepping the display vehicle. “Tony Glover (NASCAR Touring Series Technical Director) and Brad Moran suggested that we should just take it right to Barrett-Jackson and run it right across the auction block. It’s that pretty.”

But the true beauty of the new K&N racing machine extends beyond its flash to its behind-the-scenes sensibilities.

“In the long run, it’s going to save teams a bunch of money,” Greci says.

Those savings should come primarily in the man hours needed to prepare and repair damaged race cars. Greci estimates that prep and repair costs should easily be cut in half.

The secret is in performance and durability of the bolt-together flange design, which eliminates the need to cut and weld together body panels or entire body segments. When a panel is damaged, teams simply bolt on a new one. Those panels will come to teams pre-dyed on the inside with pre-molded mounting points, pre-cut glass and a built-in cowl for air induction.

“The way it bolts together, cars will be much friendlier to repair, either in tact or by reattaching panels,” Greci says. “The way the flanges work, they either butt up at a seam or overlap a seam. But there are no exposed bolts. Everything is inside. Our car for Las Vegas is painted, but if you wrapped it instead of painting it, you wouldn’t even see the seams.”

Although an entire body – be it designed for Chevrolet, Ford or Toyota – weighs only 120 pounds, Moran emphasizes that design emphasis came from a safety-first perspective.

Although an entire body – be it designed for Chevrolet, Ford or Toyota – weighs only 120 pounds, Moran emphasizes that design emphasis came from a safety-first perspective.

“First of all, it’s made from flame-resistant material,” he says. “The greenhouse is very well constructed. There are tethers to keep the hood from flying off, insets for windshield center braces, really a lot of safety improvements.”

The Las Vegas car is actually the second prototype built for the K&N Series utilizing the composite laminate materials and 11-panel design. The first car was built in a cooperative effort between body component supplier Five-Star Racing and the NASCAR Research and Development team under the watchful eye of Glover, a three-time Daytona 500-winning crew chief.

That car went through wind tunnel testing, where the new model, designed to resemble current Sprint Cup cars, compared favorably to its Sprint Cup brethren.

Given the technical numbers, although the new body won’t actually see the race track until the first weekend of the 2015 season, Feb. 6-7 at New Smyrna, Fla., K&N Series officials are confident about performance and durability.

“Based on our tests, I don’t know if the new car will really go faster, but it does look more modern,” Moran says. “It’s a big leap forward for the series in terms of aesthetics.

“By elevating the quality of the car with a look that’s more up-to-date – more what you see on the street and with a look that’s almost identical to the Sprint Cup body that fans see racing on Sundays. – I think it elevates the entire series.”

The new K&N Pro Series body is one of three NASCAR vehicle attractions on display at the SEMA Show, which runs through Nov. 7. The 2015 No. 18 Joe Gibbs Racing Toyota Camry of Sprint Cup Series driver Kyle Busch and the track-drying Air Titan 2.0 highlight the NASCAR area on the show floor.

The display also includes a Mazda Prototype race car from the TUDOR United SportsCar Championship, which is sanctioned by the International Motor Sports Association (IMSA), a company within the NASCAR Holdings Group.

Fans following the event from their computer, tablet or mobile device can watch driver interviews live on Fanschoice.tv.

Executives from NASCAR and IMSA are being featured as part of the SEMA Show’s Technology Briefing Seminars. Scott Atherton, president of IMSA, discussed the importance of technology and innovation in growing the series during the Racing and Performance Forum. Gene Stefanyshyn, senior vice president for Innovation and Racing Development, was a featured panelist on the Powertrain Forum and talked about NASCAR’s efforts to maximize fuel economy and Dr. Mike Lynch, NASCAR vice president of Green Innovation, discussed the sport’s focus on driving sustainability at the Automotive Aftermarket Products Expo on Nov. 3.